Brand:

MITSUBISHI

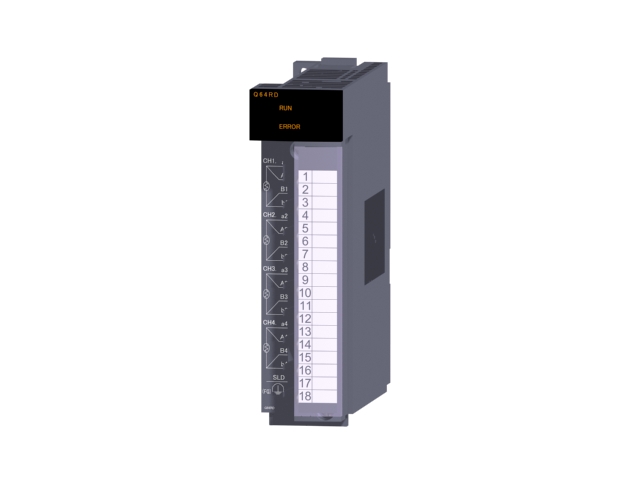

Q64RD Platinum resistance type temperature input module

MITSUBISHI Q64RD Manual And Instructions

Q64RD datasheetPDF datasheet

Q64RD HardwareUser's Manual

Q64RD User's Manual

MITSUBISHI Q64RD Product information and technical parameters:

Brand: MITSUBISHI

Name: Platinum resistance type temperature input module

Model: Q64RD

Input: 4 channels.

Platinum resistance (Pt10; JPt100).

Conversion speed: 40ms/1.

Channel 18 point terminal.

Platinum thermal resistance (Pt100, JPt100).

Nickel thermal resistance (Ni100).

Shedding detection function.

Conversion speed: 320ms/8 channel.

Inter channel isolation.

40 pin connector.

Most suitable for process control of isolated analog modules.

Temperature data can be collected by connecting thermocouple / thermal resistance.

Products can choose multi-channel (8 channel) input type and channel isolation type.

Customers can choose the most suitable model according to the intended use.

Reduce system downtime recovery time.

With a simple operation, you can back up all the data in the CPU to the memory card.

Through regular backup, can be the latest parameters, procedures, etc. to save the storage card.

In the event of a CPU failure, after the replacement of CPU, can be a simple operation,

Restore the system by using the data storage card in advance.

Therefore, it is not necessary to spend time to manage the backup data, but also can shorten the recovery time of the system shutdown.

Auto backup key data

Save the program and parameter files automatically to the program memory (ROM Flash) without using the backup battery,

To prevent the loss of the program and the parameters due to forgetting to replace the battery.

In addition, the soft component data and other important data can be backed up to the standard ROM,

In order to avoid during the long holiday and other planned downtime,

The data is lost due to battery depletion.

The next time the power is turned on, the backup data will be automatically restored.

...More relevant models >>>>

Q64RD datasheetPDF datasheet

Q64RD HardwareUser's Manual

Q64RD User's Manual

MITSUBISHI Q64RD Product information and technical parameters:

Brand: MITSUBISHI

Name: Platinum resistance type temperature input module

Model: Q64RD

Input: 4 channels.

Platinum resistance (Pt10; JPt100).

Conversion speed: 40ms/1.

Channel 18 point terminal.

Platinum thermal resistance (Pt100, JPt100).

Nickel thermal resistance (Ni100).

Shedding detection function.

Conversion speed: 320ms/8 channel.

Inter channel isolation.

40 pin connector.

Most suitable for process control of isolated analog modules.

Temperature data can be collected by connecting thermocouple / thermal resistance.

Products can choose multi-channel (8 channel) input type and channel isolation type.

Customers can choose the most suitable model according to the intended use.

Reduce system downtime recovery time.

With a simple operation, you can back up all the data in the CPU to the memory card.

Through regular backup, can be the latest parameters, procedures, etc. to save the storage card.

In the event of a CPU failure, after the replacement of CPU, can be a simple operation,

Restore the system by using the data storage card in advance.

Therefore, it is not necessary to spend time to manage the backup data, but also can shorten the recovery time of the system shutdown.

Auto backup key data

Save the program and parameter files automatically to the program memory (ROM Flash) without using the backup battery,

To prevent the loss of the program and the parameters due to forgetting to replace the battery.

In addition, the soft component data and other important data can be backed up to the standard ROM,

In order to avoid during the long holiday and other planned downtime,

The data is lost due to battery depletion.

The next time the power is turned on, the backup data will be automatically restored.

Positioning: 3 axis, built-in counter function, open collector output type.

Control unit: pulse.

Number of location data: 1/ axis.

Maximum output pulse: 100Kpps.

Counter: 3 channels.

100Kpps.

Counter input signal: DV5~24V.

40 pin connector.

Positioning control using encoder feedback, especially suitable for conveying system and processing machinery, etc Q64RD. .

In the 1 single module, the 3 axis positioning function and the 3 channel counter function are integrated Q64RD

Positioning module, high-speed counter module combined as a whole,

Can effectively use the board slot and save space. Input / output points: 4096 points.

Number of input and output elements: 8192.

Program capacity: 28 K step.

Processing speed: 34ns Q64RD.

Program memory capacity: 144 KB.

Built in RS232 communication port.

Support installed memory card.

For A mode only.

Enhance the basic performance.

CPU''s built-in soft element memory capacity increases to up to 60K.

To increase the control, quality management data can also be processed at high speed.

Convenient processing of large capacity data.

In the past can not achieve the standard RAM and SRAM card file register area of continuous access,

The boundary of each area should be considered in programming Q64RD.

The SRAM 8MB extension card is installed in the high speed universal QCPU,

Standard RAM can be used as a continuous file register,

Capacity up to 4736K words, thus simplifying the programming.

Thus, even if the memory space of the soft element is insufficient,

Can also be installed by the expansion of SRAM card, easy to extend the file register area.

The address register is extended to 32 bits, which can be programmed to go beyonnd the traditional 32K word,

And to achieve the extension to the file register to all regions of the file register Q64RD.

In addition, the processing speed of the index modification plays an important role in the efficient operation of structured daata (array),

The speed has been improved Q64RD.

When the index is used to modify the program repeatedly (e.g. from FOR to NEXT), the scan time can be reduced.

Control unit: pulse.

Number of location data: 1/ axis.

Maximum output pulse: 100Kpps.

Counter: 3 channels.

100Kpps.

Counter input signal: DV5~24V.

40 pin connector.

Positioning control using encoder feedback, especially suitable for conveying system and processing machinery, etc Q64RD. .

In the 1 single module, the 3 axis positioning function and the 3 channel counter function are integrated Q64RD

Positioning module, high-speed counter module combined as a whole,

Can effectively use the board slot and save space. Input / output points: 4096 points.

Number of input and output elements: 8192.

Program capacity: 28 K step.

Processing speed: 34ns Q64RD.

Program memory capacity: 144 KB.

Built in RS232 communication port.

Support installed memory card.

For A mode only.

Enhance the basic performance.

CPU''s built-in soft element memory capacity increases to up to 60K.

To increase the control, quality management data can also be processed at high speed.

Convenient processing of large capacity data.

In the past can not achieve the standard RAM and SRAM card file register area of continuous access,

The boundary of each area should be considered in programming Q64RD.

The SRAM 8MB extension card is installed in the high speed universal QCPU,

Standard RAM can be used as a continuous file register,

Capacity up to 4736K words, thus simplifying the programming.

Thus, even if the memory space of the soft element is insufficient,

Can also be installed by the expansion of SRAM card, easy to extend the file register area.

The address register is extended to 32 bits, which can be programmed to go beyonnd the traditional 32K word,

And to achieve the extension to the file register to all regions of the file register Q64RD.

In addition, the processing speed of the index modification plays an important role in the efficient operation of structured daata (array),

The speed has been improved Q64RD.

When the index is used to modify the program repeatedly (e.g. from FOR to NEXT), the scan time can be reduced.

...More relevant models >>>>