Brand:

MITSUBISHI

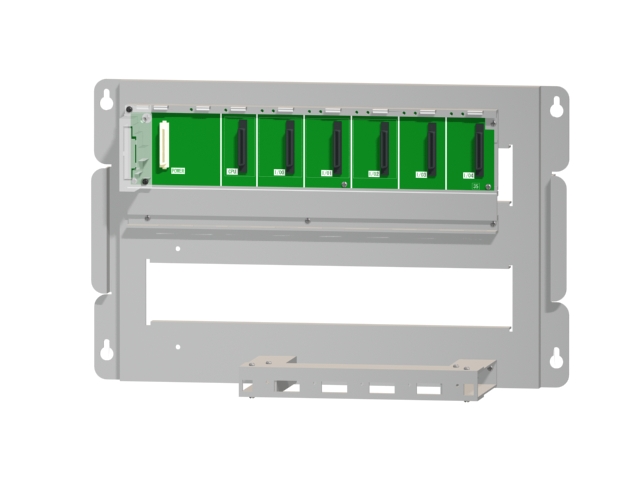

Q35BL Large main substrate

MITSUBISHI Q35BL Manual And Instructions

Q35BL datasheetPDF datasheet

Q35BL datasheetPDF datasheet

Q35BL User's Manual

MITSUBISHI Q35BL Product information and technical parameters:

Brand: MITSUBISHI

Name: Large main substrate

Model: Q35BL

5 slots.

The main substrate needs to be equipped with CPU and power supply.

Requires 1 power modules.

Used to install large Q series modules.

Optimal network matching for application purposes and applications,

Seamless communication between different hierarchical systems.

Enhancing the ability of information communication through network.

This is also a major task in the field of automation.

Network environment provided by Q series

Is truly open & seamless.

Including based on universal ethernet,

Achieve easy management of the environment "IE Control CC-Link" controller network,

As well as in its management to achieve a high-speed, high-capacity transmission of the "IE Field CC-Link" field network.

Also including Japan''s first, to achieve the world standard,

And get the SEMI certification of the field network "CC-Link",

And inherited the design concept of the provincial distribution network CC-Link/LT".

And support sensor networks "AnyWire",

To enrich the lineup flexibility to integrate the various layers of automation network.

A variety of modules with excellent performance,

Meet the needs of various control from analog to location.

Q series module products include a variety of types of I/O, analog and positioning function module.

Can fully meet the switch, sensor, such as the input and output, temperature, weight, flow and motor, drive control,

As well as the requirements of high-precision control of the positioning of the industry, the control needs of various fields.

Can also be used in combination with the CPU module to achieve appropriate control.

...More relevant models >>>>

Q35BL datasheetPDF datasheet

Q35BL datasheetPDF datasheet

Q35BL User's Manual

MITSUBISHI Q35BL Product information and technical parameters:

Brand: MITSUBISHI

Name: Large main substrate

Model: Q35BL

5 slots.

The main substrate needs to be equipped with CPU and power supply.

Requires 1 power modules.

Used to install large Q series modules.

Optimal network matching for application purposes and applications,

Seamless communication between different hierarchical systems.

Enhancing the ability of information communication through network.

This is also a major task in the field of automation.

Network environment provided by Q series

Is truly open & seamless.

Including based on universal ethernet,

Achieve easy management of the environment "IE Control CC-Link" controller network,

As well as in its management to achieve a high-speed, high-capacity transmission of the "IE Field CC-Link" field network.

Also including Japan''s first, to achieve the world standard,

And get the SEMI certification of the field network "CC-Link",

And inherited the design concept of the provincial distribution network CC-Link/LT".

And support sensor networks "AnyWire",

To enrich the lineup flexibility to integrate the various layers of automation network.

A variety of modules with excellent performance,

Meet the needs of various control from analog to location.

Q series module products include a variety of types of I/O, analog and positioning function module.

Can fully meet the switch, sensor, such as the input and output, temperature, weight, flow and motor, drive control,

As well as the requirements of high-precision control of the positioning of the industry, the control needs of various fields.

Can also be used in combination with the CPU module to achieve appropriate control.

Input / output points: 4096 points.

Number of input and output elements: 8192.

Program capacity: 30 K step.

Processing speed: 0.02 s.

Program memory capacity: 120 KB.

Support USB and network.

Support installed memory card.

Providing high speed communication between multiple CPU.

Shorten the fixed scan interrupt time, high precision device Q35BL.

The minimum interval of the fixed period interrupt program is reduced to 100 s Q35BL

The high speed signal can be accurately obtained, which makes the contribution to the higher precision of the device.

High speed and high precision machine control by multi CPU.

By parallel processing of the linear and multi CPU high-speed communication (cycle 0.88ms) of the parallel control program, the high speed control Q35BL.

Multi CPU high speed communication cycle and motion control synchronization, so it can achieve the maximization of computing efficiency.

In addition, the latest movement control CPU in performance is 2 times the previous model,

To ensure high speed and high accuracy of the machine control."Maximum control axis: 16 axis.

Connection mode with servo amplifier: SSCNET III /H connection type Q35BL.

The maximum distance between the drive units: 100m.

Operation cycle: 0.88ms, 1.77ms.

Interpolation function: linear interpolation (maximum 4 axis), 2 axis arc interpolation.

Color signal: 4 points.

Color detecting set: 16 set.

Even the long distance wiring can be flexible.

The use of fiber optic cable, with high speed, high performance, high reliability of the servo system controller network.

In addition to the traditional positioning control, but also to support speed / torque control and synchronous control.

Use simple movement module setup tool",

Can easily perform positioning settings, monitoring and debugging, etc..

In addition, the data can be collected and displayed synchronously with the motion controller.

SSCNET III /H connection to save the wiring, the maximum distance between the station up to 100m,

Absolute position system can be easily supported.

The upper limit limit switch, the lower limit switch and the near point block signal are input by the servo ammplifier,

Thus greatly reducing wiring Q35BL.

In addition to positioning control and speed control, but also to perform synchronization control, cam control, torque control, touch pressure control, etc..

Positioning module (QD75MH) of the project annd the sequence of the previous model is highly compatible with the old model,

The project can be easily applied to the simple motion module (QD77MS) Q35BL. "

Number of input and output elements: 8192.

Program capacity: 30 K step.

Processing speed: 0.02 s.

Program memory capacity: 120 KB.

Support USB and network.

Support installed memory card.

Providing high speed communication between multiple CPU.

Shorten the fixed scan interrupt time, high precision device Q35BL.

The minimum interval of the fixed period interrupt program is reduced to 100 s Q35BL

The high speed signal can be accurately obtained, which makes the contribution to the higher precision of the device.

High speed and high precision machine control by multi CPU.

By parallel processing of the linear and multi CPU high-speed communication (cycle 0.88ms) of the parallel control program, the high speed control Q35BL.

Multi CPU high speed communication cycle and motion control synchronization, so it can achieve the maximization of computing efficiency.

In addition, the latest movement control CPU in performance is 2 times the previous model,

To ensure high speed and high accuracy of the machine control."Maximum control axis: 16 axis.

Connection mode with servo amplifier: SSCNET III /H connection type Q35BL.

The maximum distance between the drive units: 100m.

Operation cycle: 0.88ms, 1.77ms.

Interpolation function: linear interpolation (maximum 4 axis), 2 axis arc interpolation.

Color signal: 4 points.

Color detecting set: 16 set.

Even the long distance wiring can be flexible.

The use of fiber optic cable, with high speed, high performance, high reliability of the servo system controller network.

In addition to the traditional positioning control, but also to support speed / torque control and synchronous control.

Use simple movement module setup tool",

Can easily perform positioning settings, monitoring and debugging, etc..

In addition, the data can be collected and displayed synchronously with the motion controller.

SSCNET III /H connection to save the wiring, the maximum distance between the station up to 100m,

Absolute position system can be easily supported.

The upper limit limit switch, the lower limit switch and the near point block signal are input by the servo ammplifier,

Thus greatly reducing wiring Q35BL.

In addition to positioning control and speed control, but also to perform synchronization control, cam control, torque control, touch pressure control, etc..

Positioning module (QD75MH) of the project annd the sequence of the previous model is highly compatible with the old model,

The project can be easily applied to the simple motion module (QD77MS) Q35BL. "

...More relevant models >>>>