Brand:

MITSUBISHI

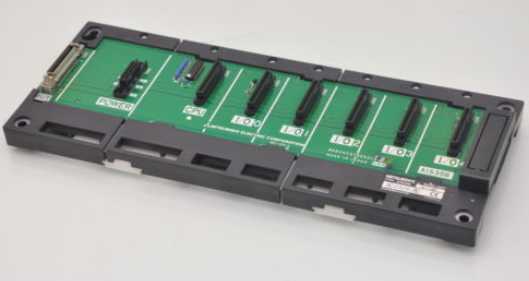

A1S35B CPU substrate

MITSUBISHI A1S35B Manual And Instructions

A1S35B datasheetPDF datasheet

MITSUBISHI A1S35B Product information and technical parameters:

Brand: MITSUBISHI

Name: CPU substrate

Model: A1S35B

I/O slots: 5 slots.

Outline dimension: 325*130.

CPU basic board can be plugged into 1 power modules,

1 CPU components and a maximum of 2, 3, 5, or 8 single slot size special function components and I/O components are respectively inserted and arranged.

Expansion ports are arranged on both sides of the base plate,

For connecting the expansion board for.

Up to 3 extension substrates.

...More relevant models >>>>

A1S35B datasheetPDF datasheet

MITSUBISHI A1S35B Product information and technical parameters:

Brand: MITSUBISHI

Name: CPU substrate

Model: A1S35B

I/O slots: 5 slots.

Outline dimension: 325*130.

CPU basic board can be plugged into 1 power modules,

1 CPU components and a maximum of 2, 3, 5, or 8 single slot size special function components and I/O components are respectively inserted and arranged.

Expansion ports are arranged on both sides of the base plate,

For connecting the expansion board for.

Up to 3 extension substrates.

Program memory capacity: 8k.

Input / output points: maximum 256 points.

A scan cycle of PLC must pass through three stages: input sampling, program execution and output refresh.

PLC in the input sampling phase: first of all, in order to scan the sequence of all existing input latches in the input terminal of the state or input data read,

And write it into the corresponding input status register,

Refresh the input, then close the input port, enter the program execution stage A1S35B A1S35B Output type: transistor source.

Output points: 16 points.

Load voltage: DC5/12/24.

Load current: 2A.

Connection mode: terminal row.

Common public end points: 8.

Switching value, also known as logic, refers to only two values, 0 or 1, ON or OFF A1S35B.

It is the most common control, it is the advantage of PLC control,

Is also the most basic application of PLC.

Switch volume control is designed to,

According to the current input combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order.

So, sometimes also known as the order control A1S35B.

And sequential control is divided into manual, semi-automatic or automatic.

And the control principle is decentralized, centralized and hybrid control three. 10Mbps transmission speed, the computer as the support of the flexible manufacturing system at the plant level, the requirements of more and more data flow,

High transmission speed can be guaranteed to increase the amount of transmitted data while maintaining the minimum time to transfer and receive data between programmable controllers.

The response time of PLC is the interval between the time of the change of the external output signal of the PLC and the time of the change of the external output signal which is controlled by it,

Lag time, this is the time constant of the input circuit,

The time constant of the output circuit, the arrangement of the user statement and the use of the instruction,

The cycle scan mode of PLC and the way of PLC to refresh the I/O and so on.

This phenomenon is called the I/O delay time effect.

Switch volume control is designed to,

According to the current inpuut combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order A1S35B.

So, sometimes also known as the order control.

And seqquential control is divided into manual, semi-automatic or automatic A1S35B.

And the control principle is decentralized, centralized and hybrid control three.

Input / output points: maximum 256 points.

A scan cycle of PLC must pass through three stages: input sampling, program execution and output refresh.

PLC in the input sampling phase: first of all, in order to scan the sequence of all existing input latches in the input terminal of the state or input data read,

And write it into the corresponding input status register,

Refresh the input, then close the input port, enter the program execution stage A1S35B A1S35B Output type: transistor source.

Output points: 16 points.

Load voltage: DC5/12/24.

Load current: 2A.

Connection mode: terminal row.

Common public end points: 8.

Switching value, also known as logic, refers to only two values, 0 or 1, ON or OFF A1S35B.

It is the most common control, it is the advantage of PLC control,

Is also the most basic application of PLC.

Switch volume control is designed to,

According to the current input combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order.

So, sometimes also known as the order control A1S35B.

And sequential control is divided into manual, semi-automatic or automatic.

And the control principle is decentralized, centralized and hybrid control three. 10Mbps transmission speed, the computer as the support of the flexible manufacturing system at the plant level, the requirements of more and more data flow,

High transmission speed can be guaranteed to increase the amount of transmitted data while maintaining the minimum time to transfer and receive data between programmable controllers.

The response time of PLC is the interval between the time of the change of the external output signal of the PLC and the time of the change of the external output signal which is controlled by it,

Lag time, this is the time constant of the input circuit,

The time constant of the output circuit, the arrangement of the user statement and the use of the instruction,

The cycle scan mode of PLC and the way of PLC to refresh the I/O and so on.

This phenomenon is called the I/O delay time effect.

Switch volume control is designed to,

According to the current inpuut combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order A1S35B.

So, sometimes also known as the order control.

And seqquential control is divided into manual, semi-automatic or automatic A1S35B.

And the control principle is decentralized, centralized and hybrid control three.

...More relevant models >>>>