Brand Sort:

MITSUBISHI

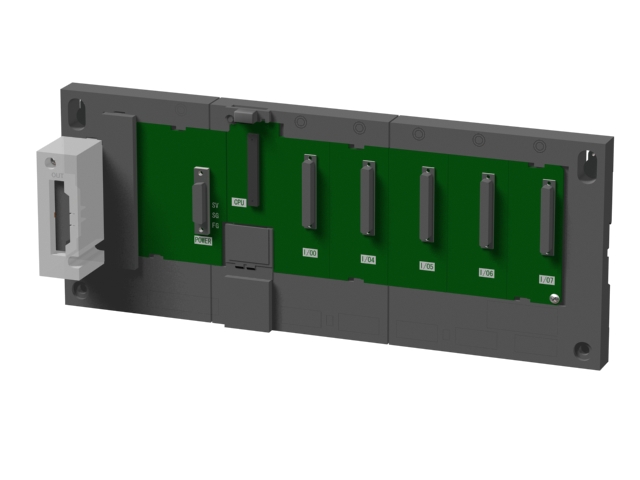

MITSUBISHI QA1S51B Price

- Brand: MITSUBISHI

- Country: JAPAN

- Name: Old small A series expansion substrate

- Model: QA1S51B

- Price: 0 >

MITSUBISHI QA1S51B

Max input / output points: 48 points.

Power supply voltage: 24VDC.

Input points: 24 points.

Output points: 24 points.

Output type: relay.

Power consumption: 30W.

Weight (kg):0.85.

Size (WxHxD) mm:182x90x87.

Note recording function, Component annotation can be recorded in the program register.

Online program editor, online change the program will not lose the working hours or stop production operation QA1S51B

RUN/STOP switch, running on panel / stop switch easy to operate.

Remote maintenance, remote programming software can monitor, upload or uninstall programs and data via modem communications

Password protection, using a eight digit password to protect your program.

Clock function and hour meter function, all of the PLC FX2N has a real-time clock standard.

Continuous scanning function, to define the operation cycle for the application of the continuous scan time.

Input filter adjustment function, you can use the input filter to smooth the input signal (in the basic unit x000 to x017). Input type: AC input.

Input points: 8 points.

Enter the response time: 20ms the following.

Rated input voltage / current: AC100V/7mA.

External connection: 2 wire.

According to the external connection mode and the external equipment input and output specifications,

Choose from a rich product lineup.

Finger protection through the upper part of the terminal,

The human body will not be exposed to live parts,

Therefore, the terminal station type remote I/O module can be directly mounted to the machine tool. DC input points: 8 points.

Input voltage and current: 7mA, DC24V.

Input response time: 10ms.

8 point /1 a public side.

Positive pole sharing.

Output points: 8 points.

Output voltage and current: DC24V.

Output response time: 2ms.

8 point /1 a public side.

Output form: transistor output, leakage type.

40 point terminal station.

MITSUBISHI PLC protection and chain procedures.

Protection and chain is an indispensable part of the program, must be carefully considered.

It can avoid the control logic confusion caused by illegal operations.

MITSUBISHI PLC initialization procedure. After MITSUBISHI PLC on power, the general need to do some of the initial operation,

In order to start making necessary preparations, to avoid the wrong operation of the system.

The main contents of the initialization program are: to some data area, counter and so on,

Data needed to restore some of the data area,

Set or reset some relays,

For some initial state display, etc..

MITSUBISHI PLC program simulation debugging

The basic idea of program simulation debugging is,

In order to facilitate the form of simulation to generate the actual state of the scene,

Create the necessary environmental conditions for the operation of the program.

Depending on the way the field signals are generated,

The simulation debugging has two forms of hardware simulation and software simulation.

QA1S51B Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=QA1S51B&select=5

Power supply voltage: 24VDC.

Input points: 24 points.

Output points: 24 points.

Output type: relay.

Power consumption: 30W.

Weight (kg):0.85.

Size (WxHxD) mm:182x90x87.

Note recording function, Component annotation can be recorded in the program register.

Online program editor, online change the program will not lose the working hours or stop production operation QA1S51B

RUN/STOP switch, running on panel / stop switch easy to operate.

Remote maintenance, remote programming software can monitor, upload or uninstall programs and data via modem communications

Password protection, using a eight digit password to protect your program.

Clock function and hour meter function, all of the PLC FX2N has a real-time clock standard.

Continuous scanning function, to define the operation cycle for the application of the continuous scan time.

Input filter adjustment function, you can use the input filter to smooth the input signal (in the basic unit x000 to x017). Input type: AC input.

Input points: 8 points.

Enter the response time: 20ms the following.

Rated input voltage / current: AC100V/7mA.

External connection: 2 wire.

According to the external connection mode and the external equipment input and output specifications,

Choose from a rich product lineup.

Finger protection through the upper part of the terminal,

The human body will not be exposed to live parts,

Therefore, the terminal station type remote I/O module can be directly mounted to the machine tool. DC input points: 8 points.

Input voltage and current: 7mA, DC24V.

Input response time: 10ms.

8 point /1 a public side.

Positive pole sharing.

Output points: 8 points.

Output voltage and current: DC24V.

Output response time: 2ms.

8 point /1 a public side.

Output form: transistor output, leakage type.

40 point terminal station.

MITSUBISHI PLC protection and chain procedures.

Protection and chain is an indispensable part of the program, must be carefully considered.

It can avoid the control logic confusion caused by illegal operations.

MITSUBISHI PLC initialization procedure. After MITSUBISHI PLC on power, the general need to do some of the initial operation,

In order to start making necessary preparations, to avoid the wrong operation of the system.

The main contents of the initialization program are: to some data area, counter and so on,

Data needed to restore some of the data area,

Set or reset some relays,

For some initial state display, etc..

MITSUBISHI PLC program simulation debugging

The basic idea of program simulation debugging is,

In order to facilitate the form of simulation to generate the actual state of the scene,

Create the necessary environmental conditions for the operation of the program.

Depending on the way the field signals are generated,

The simulation debugging has two forms of hardware simulation and software simulation.

QA1S51B Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=QA1S51B&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

Medium inertia power servo motor

HF-SP51B

Servo motor series: medium inertia, medi

MITSUBISHI

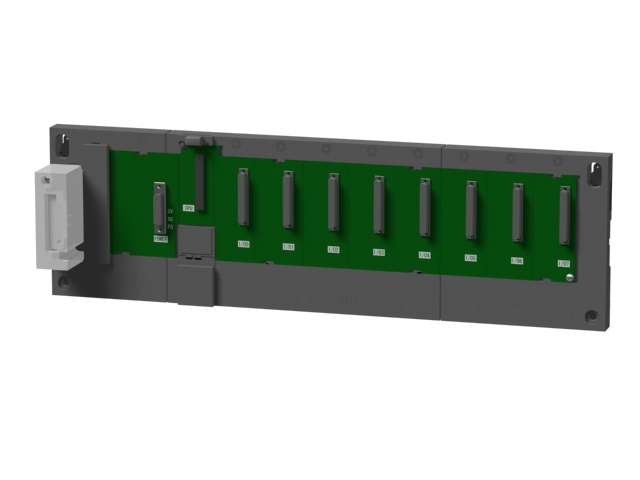

Old small A series main substrate

QA1S33B

3 slots requires 1 AnS series PLC power

MITSUBISHI

Old small A series main substrate

QA1S35B

5 slots requires 1 AnS series PLC power

MITSUBISHI

Old small A series main substrate

QA1S38B

8 slots requires 1 AnS series PLC power