Brand Sort:

MITSUBISHI

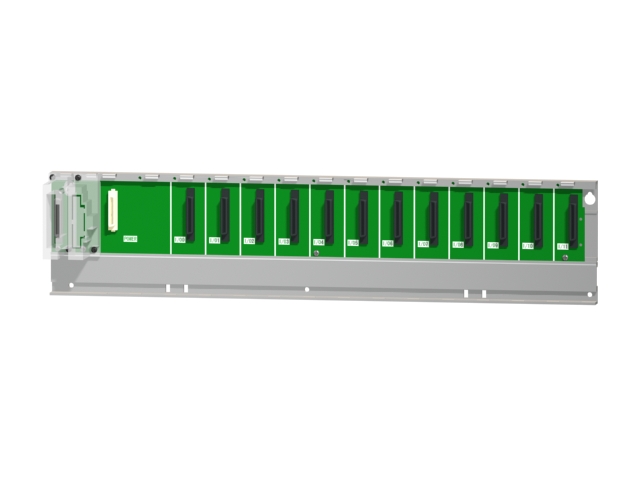

MITSUBISHI Q612B Price

- Brand: MITSUBISHI

- Country: JAPAN

- Name: Extended substrate

- Model: Q612B

- Price: U.S.$ 423.73

MITSUBISHI Q612B

For GOT multipoint connection.

Applicable models: GT15, GT16, GT11, GT10, GT27, GT25, GT23, GT21. For the GT1662-VNB.

Applicable model: GT16. Input points: 32 points.

Output points: 32 points.

Output form: transistor.

Connected programmable logic controller: FX1NC, FX2NC, FX3UC.

FX2NC expansion module can be directly connected to the FX1NC, FX2NC, PLC FX3UC on the expansion of the input and output Q612B

Do not need to connect the cable and so on, therefore can carry on the compact expansion. Motor series: low inertia, medium capacity.

Rated output power: 45.0kw.

Rated speed: 2000rpm.

With the brake: without.

Voltage: 400V level.

Shaft end: straight shaft.

Brushless motor has small size, light weight, large output, fast response, high speed, small inertia, smooth rotation, and stable torque.

Control is complex, easy to realize intelligent, and its electronic commutation method is flexible, can square wave commutation or sine wave commutation.

Motor maintenance free, high efficiency, low operating temperature, electromagnetic radiation is very small, long life, can be used for a variety of environments.

AC servo motor is brushless motor, which is divided into synchronous and asynchronous motor,

At present, the general use of synchronous motor control, which is a large range of power,

Can do a lot of power.

Large inertia, the maximum rotation speed is low, and with the increase of power and rapid reduction.

So it is suitable for the application of low speed and stable operation. Type: HF-SN servo motor, medium inertia power.

Rated output power: 3.0kw.

Rated speed: 2000r/min.

Electromagnetic brake: there.

Oil seal: have.

Encoder resolution: 131072p/r.

S100 representative: Super MR-E special motor.

KH003 special mark for Super MR-E.

High performance and easy to operate, reduce work load.

Enhanced system cost performance.

High performance, high precision positioning (servo motor encoder resolution: 131072).

High response.

Suppression of vibration by adaptive vibration suppression control.

Using personal computer and servo setup software to optimize tuning.

Has 2 types of interfaces:

Position control and speed control with pulse train interface.

The analog input interface is used for speed control and torque control.

Wide use.

Machining equipment and machine tool feed.

Used for food, packaging equipment and feeding device.

For textile machinery, etc..

Can improve the performance of equipment.

Servo amplifier terminals are used to reduce the required wiring time.

The connector is located in front of the servo amplifier, which is convenient for cable connection.

The gain adjustment can be easily carried out by the real-time automatic tuning function.

Q612B Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=Q612B&select=5

Applicable models: GT15, GT16, GT11, GT10, GT27, GT25, GT23, GT21. For the GT1662-VNB.

Applicable model: GT16. Input points: 32 points.

Output points: 32 points.

Output form: transistor.

Connected programmable logic controller: FX1NC, FX2NC, FX3UC.

FX2NC expansion module can be directly connected to the FX1NC, FX2NC, PLC FX3UC on the expansion of the input and output Q612B

Do not need to connect the cable and so on, therefore can carry on the compact expansion. Motor series: low inertia, medium capacity.

Rated output power: 45.0kw.

Rated speed: 2000rpm.

With the brake: without.

Voltage: 400V level.

Shaft end: straight shaft.

Brushless motor has small size, light weight, large output, fast response, high speed, small inertia, smooth rotation, and stable torque.

Control is complex, easy to realize intelligent, and its electronic commutation method is flexible, can square wave commutation or sine wave commutation.

Motor maintenance free, high efficiency, low operating temperature, electromagnetic radiation is very small, long life, can be used for a variety of environments.

AC servo motor is brushless motor, which is divided into synchronous and asynchronous motor,

At present, the general use of synchronous motor control, which is a large range of power,

Can do a lot of power.

Large inertia, the maximum rotation speed is low, and with the increase of power and rapid reduction.

So it is suitable for the application of low speed and stable operation. Type: HF-SN servo motor, medium inertia power.

Rated output power: 3.0kw.

Rated speed: 2000r/min.

Electromagnetic brake: there.

Oil seal: have.

Encoder resolution: 131072p/r.

S100 representative: Super MR-E special motor.

KH003 special mark for Super MR-E.

High performance and easy to operate, reduce work load.

Enhanced system cost performance.

High performance, high precision positioning (servo motor encoder resolution: 131072).

High response.

Suppression of vibration by adaptive vibration suppression control.

Using personal computer and servo setup software to optimize tuning.

Has 2 types of interfaces:

Position control and speed control with pulse train interface.

The analog input interface is used for speed control and torque control.

Wide use.

Machining equipment and machine tool feed.

Used for food, packaging equipment and feeding device.

For textile machinery, etc..

Can improve the performance of equipment.

Servo amplifier terminals are used to reduce the required wiring time.

The connector is located in front of the servo amplifier, which is convenient for cable connection.

The gain adjustment can be easily carried out by the real-time automatic tuning function.

Q612B Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=Q612B&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

Extended substrate

Q612B

12 slots.

Extended sustrate.

Requires 1

MITSUBISHI

Medium inertia medium capacity motor

HC-SF352B

Motor series: medium inertia, medium cap

MITSUBISHI

Voltage / current output analog module

Q66DA-G

Output: 6 channels.

Input resolution:

MITSUBISHI

Flat medium capacity servo motor

HG-UR352B

Servo motor series: flat type, medium ca