Brand Sort:

MITSUBISHI

MITSUBISHI Q1MEM-128SE Price

- Brand: MITSUBISHI

- Country: JAPAN

- Name: Memory card

- Model: Q1MEM-128SE

- Price: 0 >

MITSUBISHI Q1MEM-128SE

A set of 5 (LOGO removable, man-machine interface provides one).

Applicable model: A95_GOT (-M3). MITSUBISHI motor universal AC servo amplifier MELSERVO-J3 series.

Rated output: 5.0kw.

Interface type: SSCNET type III fiber communication.

Power specification: three phase AC200V.

High speed serial communication between the SSCNET and the servo amplifier by using the fastest up to 0.44ms communication cycle,

A fully synchronous control system can be constructed Q1MEM-128SE

It is only necessary to insert the special optical fiber into the joint to form SSCNET III network, which greatly reduces the wiring work and reduces the possibility of false wiring.

Due to the adoption of the optical fiber communication, the anti noise ability can be greatly improved and the long distance wiring of 50 meters (maximum 800 meters x 16 axes) can be realized.

A servo amplifier to meet the full closed loop control function MR-J3-B-RJ006.

Suitable for mechanical servo optimization and adjustment!

More advanced optimization adjustment function and control function to maximize mechanical properties. MR-J2M multi axis servo amplifier drive unit.

Rated output: 0.1kw.

Servo system is used to achieve the following purposes:

1, with a small power command signal to control the power load. Gun control and rudder control is a typical example.

2, in the absence of mechanical connection, the input shaft control is located in the distance of the output shaft, to achieve remote synchronous transmission.

3, so that the output of the mechanical displacement of the precise tracking of electrical signals, such as records and instructions, etc.. "Differential driver output.

Axis of control: 4.

Control unit: mm, inch, degree, pulse.

Location data: 600 data / axis.

Module backup function: the positioning data, module start data saved to the flash ROM (no battery).

Boot time (operation cycle 0.444ms, 1 axes): 0.3ms.

Maximum output pulse: 5000000 pulse/s.

The maximum distance between servo system: 10m.

External wiring connection: 40 pin connector two.

Linear interpolation: 2 axes.

Arc interpolation: 2 axes.

Spiral line interpolation

For large hole drilling, X, Y, Z axis should be considered.

Need to be through the milling process, along the XY axis of the circular arc shaped drill open the required specifications of the hole.

And the deviation of the cutting position is controlled at the minimum, and the shaft is carefully processed along the Z axis.

Without special NC control system for such control, X, Y, Z axis between the interpolation control is easy to produce error,

High precision positioning control.

The use of the positioning module of the spiral line interpolation function, that is, to achieve low cost control of high difficulty.

Easy positioning control

The positioning module uses the position control and speed control, which is set by the engineering software.

In the position control and speed control is also equipped with an increase in the "conditional judgment" after the implementation of the specified positioning data and other advanced positioning control functions.

For example, in the automobile door sealing process, the need to carry out high precision positioning control,

In order to applying sealant on the sealing part of the door.

Therefore, it is necessary to track the precise trajectory through the straight line and the arc, and implement the high precision interpolation control.

Multiple start mode

In addition to the conventional positioning module startup, there are high-speed start, multi axis at the same time, such as the start of a variety of ways to start.

High speed start by analyzing the location data to be executed in advance,

High speed startup mode without data analysis time.

Multi axis simultaneous start up mode for starting output pulse at the same time that the object shaft is started simultaneously with the start of the shaft.

In addition, the module can be started to run according to a plurality of positioning data groups in turn at startup.

Can be used for repetitive control of the same locus. "

Q1MEM-128SE Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=Q1MEM-128SE&select=5

Applicable model: A95_GOT (-M3). MITSUBISHI motor universal AC servo amplifier MELSERVO-J3 series.

Rated output: 5.0kw.

Interface type: SSCNET type III fiber communication.

Power specification: three phase AC200V.

High speed serial communication between the SSCNET and the servo amplifier by using the fastest up to 0.44ms communication cycle,

A fully synchronous control system can be constructed Q1MEM-128SE

It is only necessary to insert the special optical fiber into the joint to form SSCNET III network, which greatly reduces the wiring work and reduces the possibility of false wiring.

Due to the adoption of the optical fiber communication, the anti noise ability can be greatly improved and the long distance wiring of 50 meters (maximum 800 meters x 16 axes) can be realized.

A servo amplifier to meet the full closed loop control function MR-J3-B-RJ006.

Suitable for mechanical servo optimization and adjustment!

More advanced optimization adjustment function and control function to maximize mechanical properties. MR-J2M multi axis servo amplifier drive unit.

Rated output: 0.1kw.

Servo system is used to achieve the following purposes:

1, with a small power command signal to control the power load. Gun control and rudder control is a typical example.

2, in the absence of mechanical connection, the input shaft control is located in the distance of the output shaft, to achieve remote synchronous transmission.

3, so that the output of the mechanical displacement of the precise tracking of electrical signals, such as records and instructions, etc.. "Differential driver output.

Axis of control: 4.

Control unit: mm, inch, degree, pulse.

Location data: 600 data / axis.

Module backup function: the positioning data, module start data saved to the flash ROM (no battery).

Boot time (operation cycle 0.444ms, 1 axes): 0.3ms.

Maximum output pulse: 5000000 pulse/s.

The maximum distance between servo system: 10m.

External wiring connection: 40 pin connector two.

Linear interpolation: 2 axes.

Arc interpolation: 2 axes.

Spiral line interpolation

For large hole drilling, X, Y, Z axis should be considered.

Need to be through the milling process, along the XY axis of the circular arc shaped drill open the required specifications of the hole.

And the deviation of the cutting position is controlled at the minimum, and the shaft is carefully processed along the Z axis.

Without special NC control system for such control, X, Y, Z axis between the interpolation control is easy to produce error,

High precision positioning control.

The use of the positioning module of the spiral line interpolation function, that is, to achieve low cost control of high difficulty.

Easy positioning control

The positioning module uses the position control and speed control, which is set by the engineering software.

In the position control and speed control is also equipped with an increase in the "conditional judgment" after the implementation of the specified positioning data and other advanced positioning control functions.

For example, in the automobile door sealing process, the need to carry out high precision positioning control,

In order to applying sealant on the sealing part of the door.

Therefore, it is necessary to track the precise trajectory through the straight line and the arc, and implement the high precision interpolation control.

Multiple start mode

In addition to the conventional positioning module startup, there are high-speed start, multi axis at the same time, such as the start of a variety of ways to start.

High speed start by analyzing the location data to be executed in advance,

High speed startup mode without data analysis time.

Multi axis simultaneous start up mode for starting output pulse at the same time that the object shaft is started simultaneously with the start of the shaft.

In addition, the module can be started to run according to a plurality of positioning data groups in turn at startup.

Can be used for repetitive control of the same locus. "

Q1MEM-128SE Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=Q1MEM-128SE&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

Memory card

Q1MEM-64S

SRAM memory card.

RAM capacity: 64KB.

MITSUBISHI

Memory card

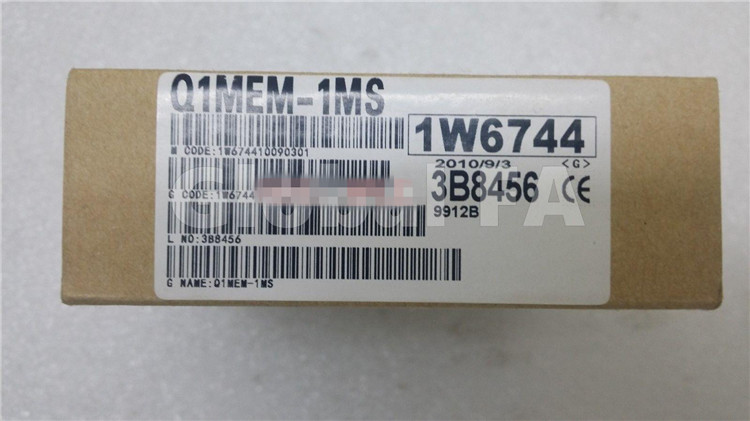

Q1MEM-1MS

SRAM memory card.

RAM capacity: 1MB.

MITSUBISHI

Memory card

Q1MEM-128SE

SRAM E2PROM memory card.

RAM capacity: 6

MITSUBISHI

Memory card

Q1MEM-2MS

SRAM memory card.

RAM capacity: 2MB.