Brand Sort:

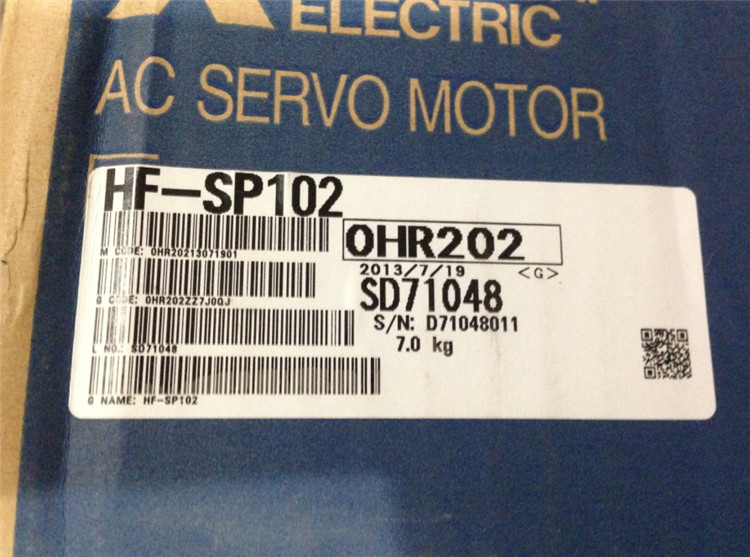

MITSUBISHI

MITSUBISHI HF-SP102K Price

- Brand: MITSUBISHI

- Country: JAPAN

- Name: Medium inertia power servo motor

- Model: HF-SP102K

- Price: U.S.$ 1230.51

MITSUBISHI HF-SP102K

Input and output points: 24 points.

Power supply: DC24V.

Input points: 14 points.

Output points: 10 points.

Output form: transistor output (drain).

Power consumption: 21W.

Weight: 0.55KG.

Outline dimension: 90x90x86mm.

FX3GE on the performance of the FX3GA increased analog input / output and Ethernet communication and other built-in features.

Applicable to a wide variety of applications.

Basic unit: 24/40 point HF-SP102K

Third generation standard model.

High flexibility.

Suitable for small scale control of high cost PLC.

Control points to 128 points, the use of CC-Link remote I/O can control the maximum 256 points.

A versatile PLC.

Built in CPU, power supply, input and output, analog input and output, Ethernet port, can be used immediately after the purchase.

High speed operation.

Basic instructions: 0.21 s/ instruction.

Application instruction: 0.5 s/ instruction.

Large capacity memory.

Built in program memory 32000 steps.

EEPROM memory cartridge with program transfer function. MITSUBISHI inverter series: FR-A820.

Voltage level: three phase 200V.

Power: 7.5kw.

SLD converter rated current: 49A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

Parameters can be selected by 4 different rated current and different overload rating (SLD (ultra light load) rated, LD (light load) rating, ND (general load) rating, HD (weight).

Type load) for selection.

You can choose the most suitable frequency converter for use; and by selecting a transducer with a SLD or LD rated level,

Be able to reduce the size of the device (compared with the FR-A700 series, to reduce the volume of equipment).

For applications that require high torque at low speeds, the HD rating is the most suitable.

The controller is used to control and monitor the frequency converter through the network.

Standard corresponding RS-485 communication (MITSUBISHI converter protocol, Modbus-RTU protocol) data transmission speed up to 115200bps. Type of input: DC leakage.

Input points: 8 points.

Input voltage: DC24.

Input current: 7mA.

Output type: transistor drain type.

Output points: 8 points.

Common public end points: 8.

PLC is introduced by the relay control technology after the development of micro processing technology,

Can be easily and reliably used for switching control.

As the analog quantity can be converted into digital quantity, the number of digital quantity is just a number of switching value,

Therefore, after the conversion of analog, PLC can also be reliable for processing control.

Because the continuous production process often has the analog quantity, the analog quantity control is sometimes called process control.

Analog quantity is not electricity, and PLC can only handle digital quantity, quantity of electricity.

All to realize the conversion between them to have the sensor, the analog quantity into a number of power.

If this power is not standard, but also through the transmitter,

The non-standard power into a standard electrical signal, such as 1-5V, 4-20mA, 0-10V, etc..

At the same time, there is also an analog input unit (A/D),

Transform these standard electrical signals into digital signals,

The analog output unit (D/A), in order to transform the digital quantity after PLC processing into analog quantity -- standard electric signal.

So the standard telecommunication number, the conversion between the number of operations to use a variety of computing.

This requires the resolution of the analog unit and the standard electrical signal.

HF-SP102K Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=HF-SP102K&select=5

Power supply: DC24V.

Input points: 14 points.

Output points: 10 points.

Output form: transistor output (drain).

Power consumption: 21W.

Weight: 0.55KG.

Outline dimension: 90x90x86mm.

FX3GE on the performance of the FX3GA increased analog input / output and Ethernet communication and other built-in features.

Applicable to a wide variety of applications.

Basic unit: 24/40 point HF-SP102K

Third generation standard model.

High flexibility.

Suitable for small scale control of high cost PLC.

Control points to 128 points, the use of CC-Link remote I/O can control the maximum 256 points.

A versatile PLC.

Built in CPU, power supply, input and output, analog input and output, Ethernet port, can be used immediately after the purchase.

High speed operation.

Basic instructions: 0.21 s/ instruction.

Application instruction: 0.5 s/ instruction.

Large capacity memory.

Built in program memory 32000 steps.

EEPROM memory cartridge with program transfer function. MITSUBISHI inverter series: FR-A820.

Voltage level: three phase 200V.

Power: 7.5kw.

SLD converter rated current: 49A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

Parameters can be selected by 4 different rated current and different overload rating (SLD (ultra light load) rated, LD (light load) rating, ND (general load) rating, HD (weight).

Type load) for selection.

You can choose the most suitable frequency converter for use; and by selecting a transducer with a SLD or LD rated level,

Be able to reduce the size of the device (compared with the FR-A700 series, to reduce the volume of equipment).

For applications that require high torque at low speeds, the HD rating is the most suitable.

The controller is used to control and monitor the frequency converter through the network.

Standard corresponding RS-485 communication (MITSUBISHI converter protocol, Modbus-RTU protocol) data transmission speed up to 115200bps. Type of input: DC leakage.

Input points: 8 points.

Input voltage: DC24.

Input current: 7mA.

Output type: transistor drain type.

Output points: 8 points.

Common public end points: 8.

PLC is introduced by the relay control technology after the development of micro processing technology,

Can be easily and reliably used for switching control.

As the analog quantity can be converted into digital quantity, the number of digital quantity is just a number of switching value,

Therefore, after the conversion of analog, PLC can also be reliable for processing control.

Because the continuous production process often has the analog quantity, the analog quantity control is sometimes called process control.

Analog quantity is not electricity, and PLC can only handle digital quantity, quantity of electricity.

All to realize the conversion between them to have the sensor, the analog quantity into a number of power.

If this power is not standard, but also through the transmitter,

The non-standard power into a standard electrical signal, such as 1-5V, 4-20mA, 0-10V, etc..

At the same time, there is also an analog input unit (A/D),

Transform these standard electrical signals into digital signals,

The analog output unit (D/A), in order to transform the digital quantity after PLC processing into analog quantity -- standard electric signal.

So the standard telecommunication number, the conversion between the number of operations to use a variety of computing.

This requires the resolution of the analog unit and the standard electrical signal.

HF-SP102K Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=HF-SP102K&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

servo motor

HF-SE152JW1-S100

Type: HF-SE servo motor, medium inertia

MITSUBISHI

Medium inertia power servo motor

HF-SP7024B

Servo motor series: medium inertia, medi

MITSUBISHI

Medium inertia power servo motor

HF-SP301

Servo motor series: medium inertia, medi

MITSUBISHI

Medium inertia power servo motor

HF-SP502

Servo motor series: medium inertia, medi