Brand Sort:

MITSUBISHI

MITSUBISHI HC-SFS202BG1 1/43 Price

- Brand: MITSUBISHI

- Country: JAPAN

- Name:

- Model: HC-SFS202BG1 1/43

- Price: U.S.$ 6074.58

MITSUBISHI HC-SFS202BG1 1/43

Memory format: EEPROM.

Number of steps: up to 8000 steps can be used.

Battery support: do not.

Method for writing and deleting: the device is installed on the PLC, and is written and deleted by the peripheral device. Motor series: medium inertia, medium power.

Rated output power: 0.5kw.

Rated speed: 2000r/min.

Whether to bring the brakes: with.

Shaft end: Standard (straight).

Power supply: 400V type HC-SFS202BG1 1/43

Protection level: IP65 (IP67).

Features: medium inertia from low speed to high speed three modes for selection, suitable for different applications.

Application examples: transmission machinery, robots, X-Y working platform.

High resolution encoder 131072p/rev (17 bit).

The encoder with high resolution ensures excellent performance and stability at low speed.

All motor dimensions are the same as before and all are compatible with the wiring. MITSUBISHI inverter FR-A740 series.

Voltage level: 3 phase 400V.

Frequency converter capacity: 3.7KW.

FR-A700 converter products are suitable for all kinds of high load requirements of the equipment.

Such as lifting, lift, printing and dyeing, printing and dyeing, material coiling and other general occasions.

High level driving performance.

Unique sensorless vector control mode,

A wide variety of mechanical equipment can be operated at high precision in the super low speed region without the need of the encoder.

With torque control mode,

And in the speed control mode can use the torque limit function.

With vector control function (with encoder),

Frequency converter can achieve position control and fast response, high precision speed control (zero speed control, servo lock, etc.) and torque control. Input type: DC input, negative public end.

Input points: 16 points.

Enter the response time: 1.5ms the following.

Rated input voltage / current: DC24V/7mA.

External connection: 2~4 line type.

Waterproof connector type.

Strong waterproof type of IP67 protection grade.

No need to stop the system can be replaced module.

Without the use of tools can be a simple connection, save time.

Terminal resistor built-in.

Can be installed along the 6 direction.

Hardware simulation method is to use a number of hardware equipment to simulate the generation of the signal,

The signals are connected to the input end of the PLC system in a hard wired way, and the timeliness is strong.

Software simulation method is in the MITSUBISHI PLC in the preparation of a set of simulation program,

The simulation provides the field signal, which is simple and easy to operate, but it is not easy to guarantee the timeliness.

Simulation of the process of debugging, debugging method can be used to segment, and the monitoring function of programmer.

HC-SFS202BG1 1/43 Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=HC-SFS202BG1 1/43&select=5

Number of steps: up to 8000 steps can be used.

Battery support: do not.

Method for writing and deleting: the device is installed on the PLC, and is written and deleted by the peripheral device. Motor series: medium inertia, medium power.

Rated output power: 0.5kw.

Rated speed: 2000r/min.

Whether to bring the brakes: with.

Shaft end: Standard (straight).

Power supply: 400V type HC-SFS202BG1 1/43

Protection level: IP65 (IP67).

Features: medium inertia from low speed to high speed three modes for selection, suitable for different applications.

Application examples: transmission machinery, robots, X-Y working platform.

High resolution encoder 131072p/rev (17 bit).

The encoder with high resolution ensures excellent performance and stability at low speed.

All motor dimensions are the same as before and all are compatible with the wiring. MITSUBISHI inverter FR-A740 series.

Voltage level: 3 phase 400V.

Frequency converter capacity: 3.7KW.

FR-A700 converter products are suitable for all kinds of high load requirements of the equipment.

Such as lifting, lift, printing and dyeing, printing and dyeing, material coiling and other general occasions.

High level driving performance.

Unique sensorless vector control mode,

A wide variety of mechanical equipment can be operated at high precision in the super low speed region without the need of the encoder.

With torque control mode,

And in the speed control mode can use the torque limit function.

With vector control function (with encoder),

Frequency converter can achieve position control and fast response, high precision speed control (zero speed control, servo lock, etc.) and torque control. Input type: DC input, negative public end.

Input points: 16 points.

Enter the response time: 1.5ms the following.

Rated input voltage / current: DC24V/7mA.

External connection: 2~4 line type.

Waterproof connector type.

Strong waterproof type of IP67 protection grade.

No need to stop the system can be replaced module.

Without the use of tools can be a simple connection, save time.

Terminal resistor built-in.

Can be installed along the 6 direction.

Hardware simulation method is to use a number of hardware equipment to simulate the generation of the signal,

The signals are connected to the input end of the PLC system in a hard wired way, and the timeliness is strong.

Software simulation method is in the MITSUBISHI PLC in the preparation of a set of simulation program,

The simulation provides the field signal, which is simple and easy to operate, but it is not easy to guarantee the timeliness.

Simulation of the process of debugging, debugging method can be used to segment, and the monitoring function of programmer.

HC-SFS202BG1 1/43 Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=HC-SFS202BG1 1/43&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

Medium inertia power motor

HC-SFS201

Motor series: medium inertia, medium pow

MITSUBISHI

Medium inertia power motor

HC-SFS202BK

Motor series: medium inertia, medium pow

MITSUBISHI

Medium inertia power motor

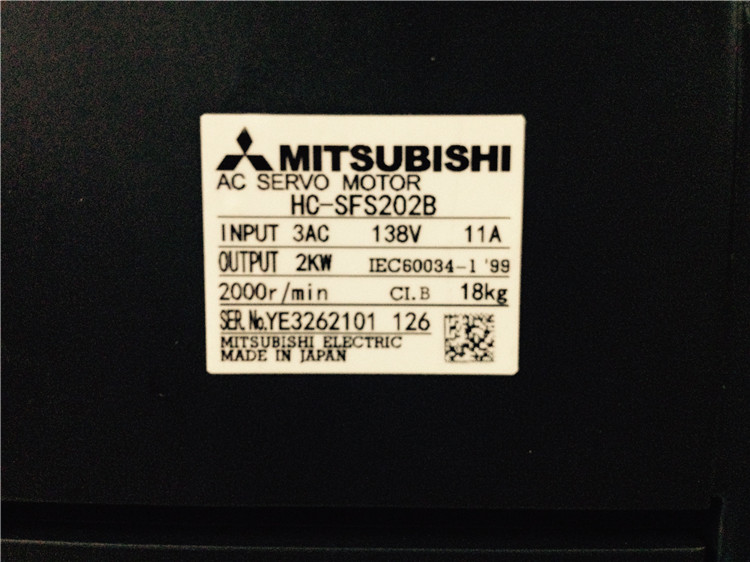

HC-SFS202B

Motor series: medium inertia, medium pow

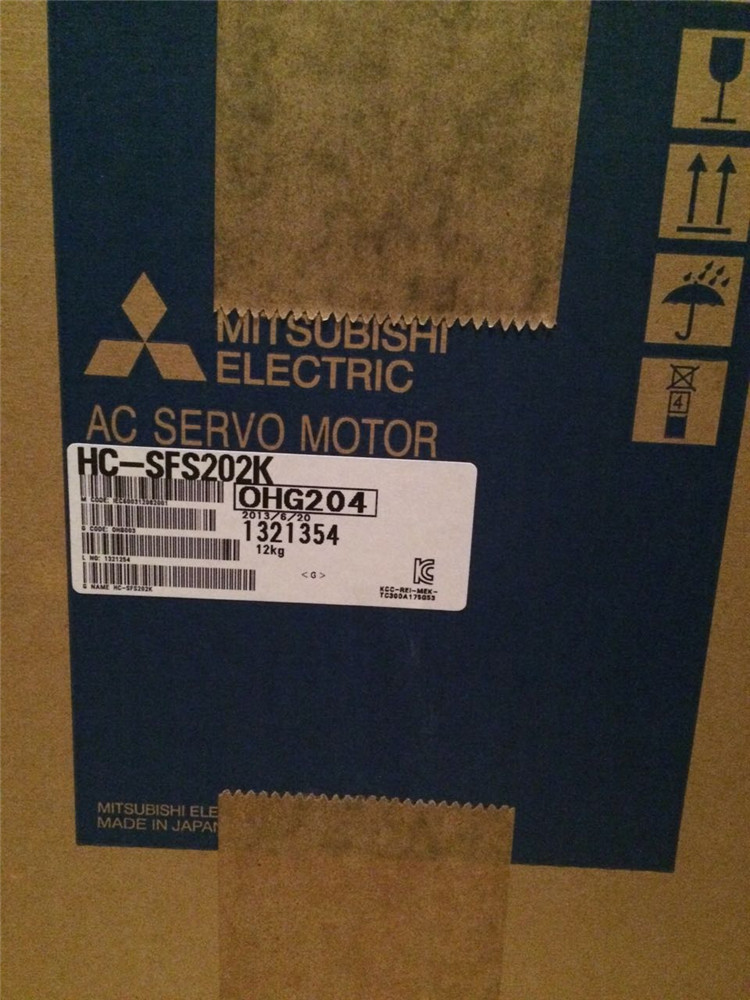

MITSUBISHI

Medium inertia power motor

HC-SFS202K

Motor series: medium inertia, medium pow