Brand Sort:

MITSUBISHI

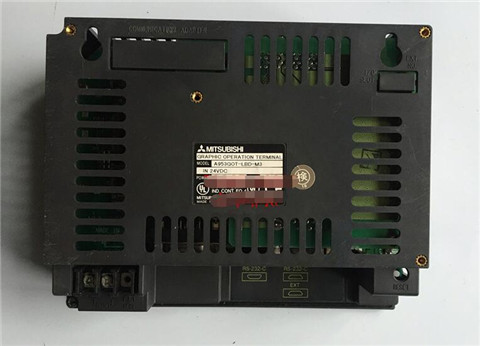

MITSUBISHI A951GOT-LBD Price

- Brand: MITSUBISHI

- Country: JAPAN

- Name: 6 inch man machine interface

- Model: A951GOT-LBD

- Price: U.S.$ 1603.39

MITSUBISHI A951GOT-LBD

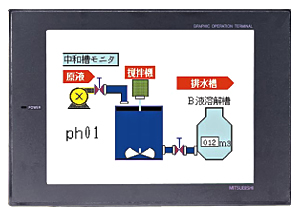

Display and setting data in a programmable controller.

Can monitor or set the timer, counter, data register.

Half the 16 characters *4, full width of 8 characters, Japanese *4 (JIS first, second), English digital. The cable is required to diagnose the function using the MRConfigurator (servo setup software) amplifier.10BASE-T

MITSUBISHI PLC is the main product in the production of MITSUBISHI motor in Dalian A951GOT-LBD

It uses a kind of programmable memory for its internal storage procedures,

Execute logic operation, sequence control, timing, counting and arithmetic operations, user oriented instruction,

And through digital or analog input / output control of various types of machinery or production process.

When the programmer input programinto the user program memory,

Then CPU according to the function of the system (the system program memory to explain the compiler),

Translate the user program into PLC internally recognized by the user to compile the program. Motor: HA-SH type.

Power: 3.5kw.

Speed: 3000r/min.

The speed regulating motor can be divided into a constant speed motor, a stepless constant speed motor, a stepless speed changing motor and a stepless speed changing motor,

Can also be divided into electromagnetic induction motor, DC motor, PWM variable frequency motor and switched reluctance motor.

The rotor speed of the induction motor is always slightly lower than that of the rotating magnetic field.

The rotor speed of the synchronous motor is not independent of the load size, but is always maintained as a synchronous speed. DC input points: 32 points.

Input voltage and current: 3/7mA, DC12/24V.

Response time: 10ms.

Positive pole sharing.

Output points: 16 points.

Output voltage and current: 100mA/1, DC12/24V point.

Response time: 2ms.

48 point /1 public side (input and output sharing).

Output form: transistor output, leakage type.

40 pin connector.

Number of stations: 1 stops.

Type remote I/O unit (twisted pair data connection).

According to the control requirements of the system, using the appropriate design method to design MITSUBISHI PLC program.

Procedures to meet the requirements of system control as the main line,

Write one by one to achieve the control function or the sub task of the program,

Gradually improve the functions specified by the system.

MITSUBISHI PLC detection, fault diagnosis and display and other procedures.

These procedures are relatively independent, generally in the basic completion of the program design and then add.

Hardware simulation method is to use a number of hardware equipment to simulate the generation of the signal,

The signals are connected to the input end of the PLC system in a hard wired way, and the timeliness is strong.

Software simulation method is in the MITSUBISHI PLC in the preparation of a set of simulation program,

The simulation provides the field signal, which is simple and easy to operate, but it is not easy to guarantee the timeliness.

Simulation of the process of debugging, debugging method can be used to segment, and the monitoring function of programmer.

A951GOT-LBD Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A951GOT-LBD&select=5

Can monitor or set the timer, counter, data register.

Half the 16 characters *4, full width of 8 characters, Japanese *4 (JIS first, second), English digital. The cable is required to diagnose the function using the MRConfigurator (servo setup software) amplifier.10BASE-T

MITSUBISHI PLC is the main product in the production of MITSUBISHI motor in Dalian A951GOT-LBD

It uses a kind of programmable memory for its internal storage procedures,

Execute logic operation, sequence control, timing, counting and arithmetic operations, user oriented instruction,

And through digital or analog input / output control of various types of machinery or production process.

When the programmer input programinto the user program memory,

Then CPU according to the function of the system (the system program memory to explain the compiler),

Translate the user program into PLC internally recognized by the user to compile the program. Motor: HA-SH type.

Power: 3.5kw.

Speed: 3000r/min.

The speed regulating motor can be divided into a constant speed motor, a stepless constant speed motor, a stepless speed changing motor and a stepless speed changing motor,

Can also be divided into electromagnetic induction motor, DC motor, PWM variable frequency motor and switched reluctance motor.

The rotor speed of the induction motor is always slightly lower than that of the rotating magnetic field.

The rotor speed of the synchronous motor is not independent of the load size, but is always maintained as a synchronous speed. DC input points: 32 points.

Input voltage and current: 3/7mA, DC12/24V.

Response time: 10ms.

Positive pole sharing.

Output points: 16 points.

Output voltage and current: 100mA/1, DC12/24V point.

Response time: 2ms.

48 point /1 public side (input and output sharing).

Output form: transistor output, leakage type.

40 pin connector.

Number of stations: 1 stops.

Type remote I/O unit (twisted pair data connection).

According to the control requirements of the system, using the appropriate design method to design MITSUBISHI PLC program.

Procedures to meet the requirements of system control as the main line,

Write one by one to achieve the control function or the sub task of the program,

Gradually improve the functions specified by the system.

MITSUBISHI PLC detection, fault diagnosis and display and other procedures.

These procedures are relatively independent, generally in the basic completion of the program design and then add.

Hardware simulation method is to use a number of hardware equipment to simulate the generation of the signal,

The signals are connected to the input end of the PLC system in a hard wired way, and the timeliness is strong.

Software simulation method is in the MITSUBISHI PLC in the preparation of a set of simulation program,

The simulation provides the field signal, which is simple and easy to operate, but it is not easy to guarantee the timeliness.

Simulation of the process of debugging, debugging method can be used to segment, and the monitoring function of programmer.

A951GOT-LBD Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A951GOT-LBD&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

6 inch man machine interface

A953GOT-LBD

Series Name: A953GOT.

Size: 6 inches.

Re

MITSUBISHI

6 inch man machine interface

A951GOT-QSBD

Series Name: A951GOT.

Size: 6 inches.

Re

MITSUBISHI

6 inch man machine interface

A951GOT-SBD-M3

Series Name: A951GOT.

Size: 6 inches.

Re

MITSUBISHI

10 inch man machine interface

A970GOT-LBD

Series Name: A975GOT.

Size: 10 inches.

R