Brand Sort:

MITSUBISHI

MITSUBISHI RQ612B Price

- Brand: MITSUBISHI

- Country: JAPAN

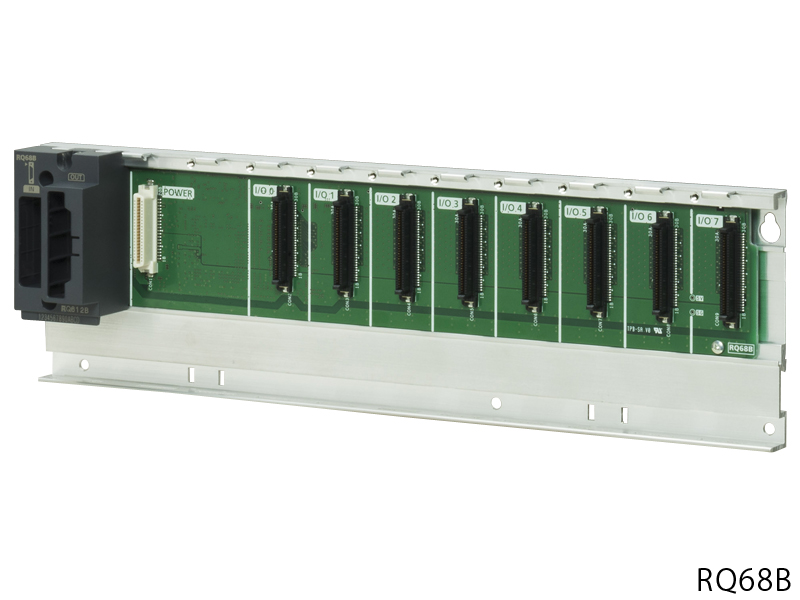

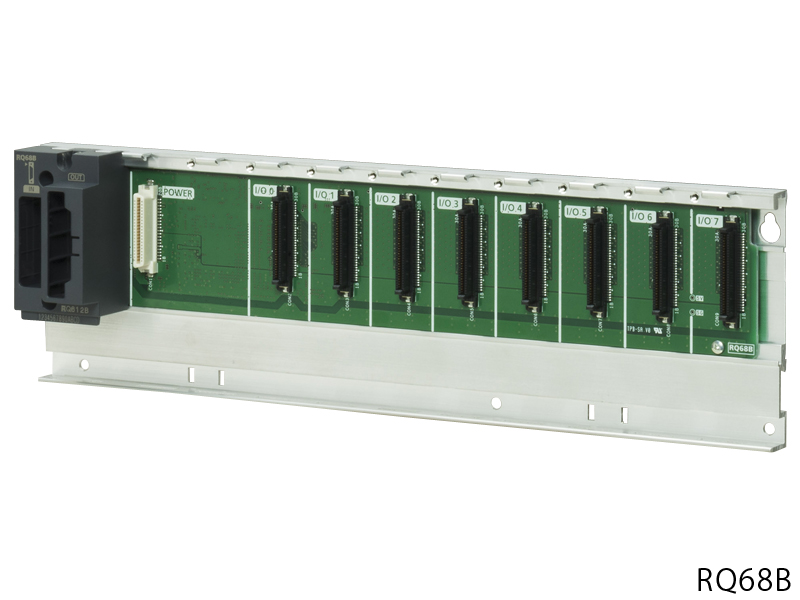

- Name: RQ extended substrate

- Model: RQ612B

- Price: 0 >

MITSUBISHI RQ612B

For A6TBXE/A6TBY36E/A6TBX54E/A6TBY54E/A6TBX70E (common cathode; source) long 1m.Input type: DC input, positive common end.

Input points: 16 points.

Enter the response time: 1.5ms the following.

Rated input voltage / current: DC24V/7mA.

Output form: transistor output, leakage type.

Output points: 16 points.

OFF leakage current: 0.25mA.

Output protection function.

Rated load voltage / current: DC24V/0 RQ612B5A.

External connection: 1 line /1 line type.

According to the external connection mode and the external equipment input and output specifications,

Choose from a rich product lineup.

Finger protection through the upper part of the terminal,

The human body will not be exposed to live parts,

Therefore, the terminal station type remote I/O module can be directly mounted to the machine tool. Servo motor series: medium inertia, small capacity.

Rated output: 2.0kw.

Rated speed: 2000r/min.

Electromagnetic brake: incidental.

Oil seal: incidental (Note 1, note 2, note 3).

Power supply: 200V.

Note 1 through HG-KR and HG-MR series 0.1kW and HG-SR series can be supported.

Note 2 with the speed reducer case, do not configure the oil seal.

Note 3 with oil seal HG-KR, HG-MR series servo motor''s appearance size standard is different.

Stable driving of medium capacity and medium inertia type products.

Through the optimization of structural design, to achieve the minimum length of the industry.

High speed & high torque. Shorten the positioning time, achieve high-speed equipment.

Reducing the electric torque ripple.

Through the combination of the optimal number of the motor and the slot number, the torque ripple is greatly reduced,

To further realize the smooth constant speed device.

Improve the environmental performance of HG-SR, HG-JR series of products using IP67. Type: HF-KN servo motor, low inertia, low power.

Rated output power: 0.75kw.

Rated speed: 3000r/min.

Electromagnetic brake: there.

Oil seal: have.

Encoder resolution: 131072p/r.

S100 representative: Super MR-E special motor.

KH003 special mark for Super MR-E.

High performance and easy to operate, reduce work load.

Enhanced system cost performance.

High performance, high precision positioning (servo motor encoder resolution: 131072).

High response.

Suppression of vibration by adaptive vibration suppression control.

Using personal computer and servo setup software to optimize tuning.

Has 2 types of interfaces:

Position control and speed control with pulse train interface.

The analog input interface is used for speed control and torque control.

Wide use.

Machining equipment and machine tool feed.

Used for food, packaging equipment and feeding device.

For textile machinery, etc..

Can improve the performance of equipment.

Servo amplifier terminals are used to reduce the required wiring time.

The connector is located in front of the servo amplifier, which is convenient for cable connection.

The gain adjustment can be easily carried out by the real-time automatic tuning function.

RQ612B Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=RQ612B&select=5

Input points: 16 points.

Enter the response time: 1.5ms the following.

Rated input voltage / current: DC24V/7mA.

Output form: transistor output, leakage type.

Output points: 16 points.

OFF leakage current: 0.25mA.

Output protection function.

Rated load voltage / current: DC24V/0 RQ612B5A.

External connection: 1 line /1 line type.

According to the external connection mode and the external equipment input and output specifications,

Choose from a rich product lineup.

Finger protection through the upper part of the terminal,

The human body will not be exposed to live parts,

Therefore, the terminal station type remote I/O module can be directly mounted to the machine tool. Servo motor series: medium inertia, small capacity.

Rated output: 2.0kw.

Rated speed: 2000r/min.

Electromagnetic brake: incidental.

Oil seal: incidental (Note 1, note 2, note 3).

Power supply: 200V.

Note 1 through HG-KR and HG-MR series 0.1kW and HG-SR series can be supported.

Note 2 with the speed reducer case, do not configure the oil seal.

Note 3 with oil seal HG-KR, HG-MR series servo motor''s appearance size standard is different.

Stable driving of medium capacity and medium inertia type products.

Through the optimization of structural design, to achieve the minimum length of the industry.

High speed & high torque. Shorten the positioning time, achieve high-speed equipment.

Reducing the electric torque ripple.

Through the combination of the optimal number of the motor and the slot number, the torque ripple is greatly reduced,

To further realize the smooth constant speed device.

Improve the environmental performance of HG-SR, HG-JR series of products using IP67. Type: HF-KN servo motor, low inertia, low power.

Rated output power: 0.75kw.

Rated speed: 3000r/min.

Electromagnetic brake: there.

Oil seal: have.

Encoder resolution: 131072p/r.

S100 representative: Super MR-E special motor.

KH003 special mark for Super MR-E.

High performance and easy to operate, reduce work load.

Enhanced system cost performance.

High performance, high precision positioning (servo motor encoder resolution: 131072).

High response.

Suppression of vibration by adaptive vibration suppression control.

Using personal computer and servo setup software to optimize tuning.

Has 2 types of interfaces:

Position control and speed control with pulse train interface.

The analog input interface is used for speed control and torque control.

Wide use.

Machining equipment and machine tool feed.

Used for food, packaging equipment and feeding device.

For textile machinery, etc..

Can improve the performance of equipment.

Servo amplifier terminals are used to reduce the required wiring time.

The connector is located in front of the servo amplifier, which is convenient for cable connection.

The gain adjustment can be easily carried out by the real-time automatic tuning function.

RQ612B Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=RQ612B&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

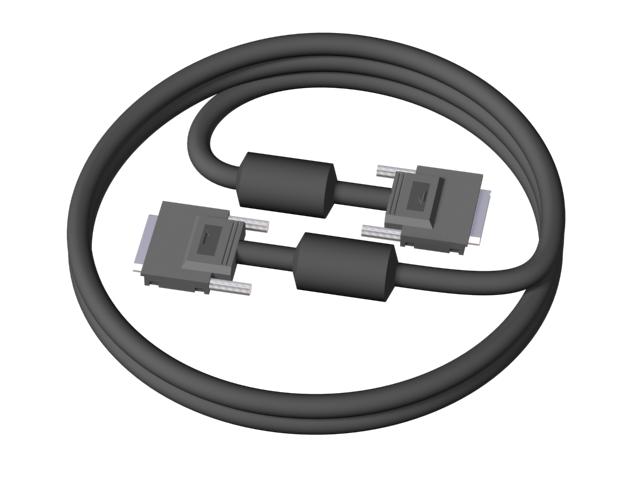

Extension cable

QC12B

Cale length 1.2 meters.

Extended sustr

MITSUBISHI

Bus connection cable for QCPU (Q mode)

GT15-QC12B

Cale length: 1.2m.

For the connection

MITSUBISHI

Extended substrate

R612B

The input and output module installation

MITSUBISHI

RQ extended substrate

RQ68B

The input and output module installation