Brand Sort:

MITSUBISHI

MITSUBISHI HC-SF121B Price

- Brand: MITSUBISHI

- Country: JAPAN

- Name: Medium inertia medium capacity motor

- Model: HC-SF121B

- Price: 0 >

MITSUBISHI HC-SF121B

CPU:A2SHCPU PLC is the same.

PLC program capacity: 30K step.

I/O points: 1024 points.

Processing speed (sequential order): 0.25 s/ step.

Control axis: up to 8.

Servo program capacity: 13K step.

Servo amplifier: SSCNET connected external servo amplifier.

PLC programming has a wide range of applications, powerful, easy to use, has become one of the main devices of modern industrial automation,

In all areas of industrial production has been widely used,

Applications in other areas (such as civil and home automation) have also been rapidly developed HC-SF121B

It uses programmable memory,

An instruction used to perform logical operations, sequence control, timing, counting and arithmetic operations in its internal storage,

And through digital, analog input and output,

Control of various types of machinery or production processes. Programmable controller and related equipment,

Should be easy to make the industrial control system to form a whole, easy to expand the principle design of its functions.

As can be seen from the above definition, PLC is a program to change the control function of the industrial control computer,

In addition to the completion of a wide variety of control functions, as well as with other computer communications networking features. Analog input points: 8 channels

Voltage input range: DC-10~10V.

Current input range: DC4~20mA, DC-20~20mA.

The resolution of 14 bit binary + symbol 1 bit, 13 bit binary + symbol 1 bit analog input module.

Voltage input, current input, thermocouple temperature sensor input of the 8 channel can be carried out.

The channel can be used as the unit, the mixed use of voltage, current, thermocouple input. Analog input points: 4 points (thermocouple, PT, constant voltage input).

Output points: transistor output 4 points, 4 point CT input.

Weight: 0.4KG.

Temperature sensor with 4CH input control output,

Double position control, standard PID control,

Heating and cooling PID control, cascade control.

By using the combination of the analog output module,

PID control of voltage or current can be realized.

New with cascade control. Through the master / slave station of the 2 controllers,

According to the temperature change caused by external disturbance, the temperature can be adjusted quickly.

Can connect FX3GA/FX3G, FX3GE, FX3U series.

When connecting to FX3UC or FX3GC, you need FX2NC-CNV-IF or FX3UC-IPS-5V.

HC-SF121B Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=HC-SF121B&select=5

PLC program capacity: 30K step.

I/O points: 1024 points.

Processing speed (sequential order): 0.25 s/ step.

Control axis: up to 8.

Servo program capacity: 13K step.

Servo amplifier: SSCNET connected external servo amplifier.

PLC programming has a wide range of applications, powerful, easy to use, has become one of the main devices of modern industrial automation,

In all areas of industrial production has been widely used,

Applications in other areas (such as civil and home automation) have also been rapidly developed HC-SF121B

It uses programmable memory,

An instruction used to perform logical operations, sequence control, timing, counting and arithmetic operations in its internal storage,

And through digital, analog input and output,

Control of various types of machinery or production processes. Programmable controller and related equipment,

Should be easy to make the industrial control system to form a whole, easy to expand the principle design of its functions.

As can be seen from the above definition, PLC is a program to change the control function of the industrial control computer,

In addition to the completion of a wide variety of control functions, as well as with other computer communications networking features. Analog input points: 8 channels

Voltage input range: DC-10~10V.

Current input range: DC4~20mA, DC-20~20mA.

The resolution of 14 bit binary + symbol 1 bit, 13 bit binary + symbol 1 bit analog input module.

Voltage input, current input, thermocouple temperature sensor input of the 8 channel can be carried out.

The channel can be used as the unit, the mixed use of voltage, current, thermocouple input. Analog input points: 4 points (thermocouple, PT, constant voltage input).

Output points: transistor output 4 points, 4 point CT input.

Weight: 0.4KG.

Temperature sensor with 4CH input control output,

Double position control, standard PID control,

Heating and cooling PID control, cascade control.

By using the combination of the analog output module,

PID control of voltage or current can be realized.

New with cascade control. Through the master / slave station of the 2 controllers,

According to the temperature change caused by external disturbance, the temperature can be adjusted quickly.

Can connect FX3GA/FX3G, FX3GE, FX3U series.

When connecting to FX3UC or FX3GC, you need FX2NC-CNV-IF or FX3UC-IPS-5V.

HC-SF121B Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=HC-SF121B&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

Medium inertia medium capacity motor

HC-SF153

Motor series: medium inertia, medium cap

MITSUBISHI

Medium inertia power motor

HC-SFS3524B

Motor series: medium inertia, medium pow

MITSUBISHI

Medium inertia medium capacity motor

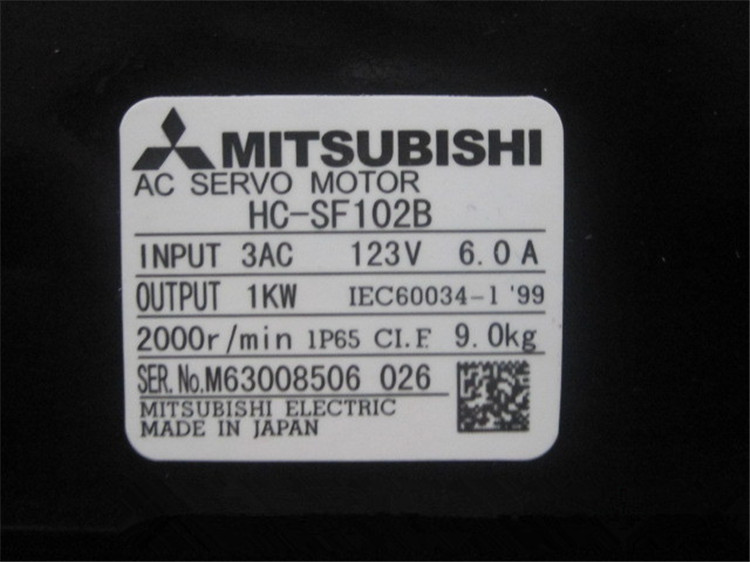

HC-SF102B

Motor series: medium inertia, medium cap

MITSUBISHI

Medium inertia power motor

HC-SFS201

Motor series: medium inertia, medium pow