Brand Sort:

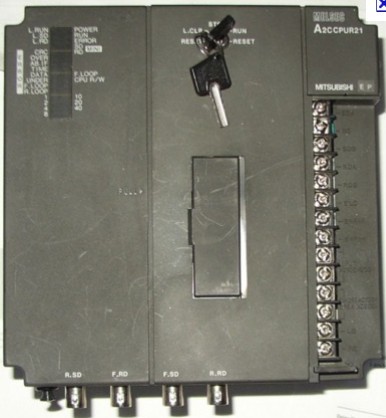

MITSUBISHI

MITSUBISHI A2CCPU-D24V Price

- Brand: MITSUBISHI

- Country: JAPAN

- Name: cpu module

- Model: A2CCPU-D24V

- Price: 0 >

MITSUBISHI A2CCPU-D24V

MITSUBISHI inverter series: FR-A800.

Voltage level: three phase 400V.

Power: 160kw.

SLD converter rated current: 432A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

Mirror like ultra fine processing.

In order to adapt to the new material diversification, the machine adopts the most cutting-edge technology, more than ever more slim hard.

In order to be able to realize the fine cutting, grinding on the hard and hard material,

The need for high-speed operation has become more and more strong A2CCPU-D24V

In order to cope with the increasing demand of logistics, every port in the world has a crane in every day.

A container filled with cargo.

We can achieve a new type of inverter products under the conditions of low speed and high torque to achieve smooth cargo handling operations,

Carry on the smooth movement to the heavy. MITSUBISHI motor universal AC servo amplifier MELSERVO-J3 series.

Rated output: 22.0kw.

Interface type: SSCNET type III fiber communication.

Special specification: suitable for linear servo motor.

Power specification: three phase AC400V.

More advanced real-time automatic tuning by setting response values,

Including the position gain and the gain of speed, all the gain can be adjusted automatically.

32 segment response level can be set.

Advanced vibration suppression control.

An optimal vibration control filter value is automatically set by the automatic tuning function to effectively suppress the vibration of the 100Hz frequency that occurs when the driving part stops.

The automatic tuning function can effectively restrain the vibration of the end of the mechanical arm and reduce the residual vibration in the machine. MITSUBISHI inverter series: FR-F840.

Voltage level: three phase 400V.

Power: 315kw.

SLD converter rated current: 683A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

The motor efficiency is not changed in the previous optimal excitation control,

At the same time, the newly developed advanced optimal excitation control can obtain larger torque at startup.

No need to adjust the parameters (plus deceleration time or torque, etc.), in a short time to speed up to a certain speed,

Can be carried out to maximize the efficiency of energy-saving drive motor.

The automatic tuning function of the loop constant of the motor is not consistent with the constant of the motor, the motor of other manufacturers, and the length of wiring is too long,

Optimum operating characteristic drive motor.

In the state of the sensor can not only drive the high efficiency and energy saving motor and PM motor (MM-EFS), but also can drive other companies induction motor and PM motor (permanent magnet synchronous motor).

Other manufacturers of induction motors, can also be automatically tuned to achieve the best excitation control, thus expanding the use of energy saving.

A2CCPU-D24V Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A2CCPU-D24V&select=5

Voltage level: three phase 400V.

Power: 160kw.

SLD converter rated current: 432A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

Mirror like ultra fine processing.

In order to adapt to the new material diversification, the machine adopts the most cutting-edge technology, more than ever more slim hard.

In order to be able to realize the fine cutting, grinding on the hard and hard material,

The need for high-speed operation has become more and more strong A2CCPU-D24V

In order to cope with the increasing demand of logistics, every port in the world has a crane in every day.

A container filled with cargo.

We can achieve a new type of inverter products under the conditions of low speed and high torque to achieve smooth cargo handling operations,

Carry on the smooth movement to the heavy. MITSUBISHI motor universal AC servo amplifier MELSERVO-J3 series.

Rated output: 22.0kw.

Interface type: SSCNET type III fiber communication.

Special specification: suitable for linear servo motor.

Power specification: three phase AC400V.

More advanced real-time automatic tuning by setting response values,

Including the position gain and the gain of speed, all the gain can be adjusted automatically.

32 segment response level can be set.

Advanced vibration suppression control.

An optimal vibration control filter value is automatically set by the automatic tuning function to effectively suppress the vibration of the 100Hz frequency that occurs when the driving part stops.

The automatic tuning function can effectively restrain the vibration of the end of the mechanical arm and reduce the residual vibration in the machine. MITSUBISHI inverter series: FR-F840.

Voltage level: three phase 400V.

Power: 315kw.

SLD converter rated current: 683A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

The motor efficiency is not changed in the previous optimal excitation control,

At the same time, the newly developed advanced optimal excitation control can obtain larger torque at startup.

No need to adjust the parameters (plus deceleration time or torque, etc.), in a short time to speed up to a certain speed,

Can be carried out to maximize the efficiency of energy-saving drive motor.

The automatic tuning function of the loop constant of the motor is not consistent with the constant of the motor, the motor of other manufacturers, and the length of wiring is too long,

Optimum operating characteristic drive motor.

In the state of the sensor can not only drive the high efficiency and energy saving motor and PM motor (MM-EFS), but also can drive other companies induction motor and PM motor (permanent magnet synchronous motor).

Other manufacturers of induction motors, can also be automatically tuned to achieve the best excitation control, thus expanding the use of energy saving.

A2CCPU-D24V Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A2CCPU-D24V&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

CPU unit

A2CCPU

Input and output points: 512 points.

Inp

MITSUBISHI

CPU unit

A2CCPUR21

Input and output points: 512 points.

Inp

MITSUBISHI

CPU unit

A2CCPUP21

Input and output points: 512 points.

Inp